Cortado Ventures is thrilled to have recently invested in Fluid Efficiency, a California-based polymer materials company focused on the oil and gas industry. The company is part of the EIC Rose Rock Bridge Program and is setting up their large-scale manufacturing facility in Tulsa. Read on to learn more about the company, our investment, and how this technology will increase capacity and efficiency in pipelines.

The Context: What is a Drag-Reducing Agent and Why is it Important?

Have you ever thought about how the gasoline we put into our car got from the oilfield to the gas station? A key piece of helping crude oil move from the oilfield to the processing plant for it to become gasoline is an additive called a drag-reducing agent, or DRA.

DRAs are additives in pipelines that reduce frictional pressure loss[1] during fluid flow. They reduce turbulence in the flow which results in increased pipeline capacity and reduced pumping energy. Drag-reducing agents are mainly used in the oil and gas industry, where they help to transport fluids over long distances.

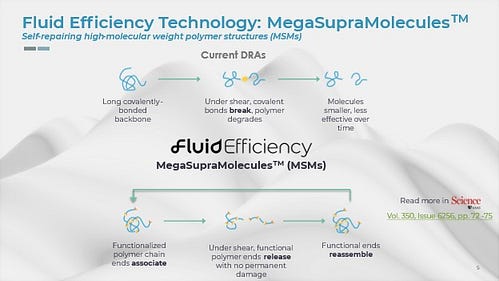

Fluids in crude oil and refined product pipelines experience high turbulence which increases the energy required to move these fluids. Existing drag-reducing agents are ultra-high molecular weight polymers[2] that break when they pass through intermediate pump stations due to the high shear environment of the pump. Once these bonds break it is almost impossible for the original length of these polymers to reform, hence at each pumping station DRA must be reinjected. When the polymer backbone of theses DRAs are broken, they lose their rheological[3] properties and must be reinjected after each pumping station. Therefore, in the absence of re-injection, the DRA loses its impact on the fluid moving through the pipeline.

DRA has limitations as well in terms of the amount of DRA that is allowed in the pipeline. When the fluid arrives at the end of the pipeline, it is tested to ensure that the concentration (in parts per million, aka PPM) of the DRA in the pipeline does not exceed a certain limit dependent on the fluid moving through the pipeline. When DRA is having to be reinjected into the pipeline at each injection site, a recalculation has to be performed to ensure that there is not too much DRA released into the pipeline.

The Technology

Fluid Efficiency differentiates their product from DRA market competitors by applying their patented Mega-Supra-Molecule (MSM) technology as a flow improver. The use of MSMs allows fora large hydrocarbon polymer assembly to be formed in the flow, which moves through the pipelines and breaks in a controlled manner at the intermediate pump stations, rejoining afterwards without losing the structural integrity of the polymer assembly. MSMs keep working long after existing DRAs are destroyed. If you can think of how Velcro acts, these MSM polymers have Velcro-like ends that allow for the polymer to reconnect and the flow improvement effect to be retained throughout the pipeline. The conventional DRA must be added at each pump due to the DRA polymers breaking down and not being able to rejoin once passing through the pump.

Using MSMs as flow improvers reduce costs by enabling pipelines to operate with far fewer reinjection points and significantly lower cumulative volumes of material without any compromise in flow rates. MSMs can also be used to increase pipeline throughput using the same amount of energy. Below the table compares the frequency of DRA injections into the pipeline, efficacy of the DRA throughout the pipeline, and an idea of the cost comparison for the overall DRA using a typical 10-injection pipeline.

Why Cortado Invested

1. An incredible team — Dr. Simon Jones, Dr. Jeremy Wei, and Dr. Julie Kornfield are thought leaders and experts within the fields of chemistry and chemical engineering. They have demonstrated technical expertise and knowledge of how to scale a commercially viable product and build additional use cases. Dr. Jones previously worked at NASA’s JPL on battery technologies for space probes destined for the moons of Jupiter and has successfully commercialized technology out of CalTech at Contour Energy Systems. Dr. Wei is a chemical engineer with extensive expertise in the polymerization techniques that developed FE’s MegaSupraMolecules. Dr. Kornfield has been a Professor of chemical engineering at Caltech for 30+ years and has expertise in polymerization and rheology. She has co-founded start-up companies that have commercialized polymers for human optical lens implants.. It is clear that when founders with such deep expertise decide to go all in on a technology it is worth investing in.

2. Value Proposition — The technology has a very clear and concise value proposition to customers driving additional revenue through existing infrastructure and cost savings, and operational efficiencies. Having multiple DRA injection sites adds logistical and operational costs to the operator. Total polymer PPM limits reduce the total amount of conventional DRA that can be injected at each injection site, limiting their useful efficacy. FE’s MSM flow improver can be injected at full strength at the start of a pipeline providing superior performance over the entire pipeline, reducing costs, and reducing logistical and operational complexity for midstream companies.

3. Ability to Disrupt Market — DRA is currently supplied to midstream companies by a few large incumbent suppliers that account for 83% of market share between the top two. According to industry professionals the total market for DRA is $2B. Suppliers lack any incentive to innovate in the space providing a great opportunity for disruption. FE’s MSM flow improver delivers increased performance at a lower cost, which will enable rapid market share capture.

Looking Ahead

At Cortado Ventures, we are dedicated to supporting groundbreaking technologies and visionary entrepreneurs who strive to create economic opportunities in the state and improve current processes. Our hope is that this investment in Fluid Efficiency is a signal to other companies to also bring operations into the region. Dr. Jones and his team are new to the area, but through the EIC Rose Rock Bridge Program have discovered Oklahoma has much to offer in terms of talent, resources, and funding. Oklahoma is truly unique and becoming a state more companies are seeking to move their business to.

Cheers to innovation and growing Oklahoma!

About Cortado Ventures

Cortado Ventures is an early-stage venture capital firm that invests in ambitious, growth-driven companies, backing a new generation of economic prosperity for the Midcontinent region, defined as Oklahoma, Texas, Arkansas, Missouri, Colorado, Kansas and New Mexico. As one of the largest VC funds in Oklahoma, Cortado’s focus is on tech companies bringing innovative solutions to the energy and logistics, life sciences, and the future of work sectors. For more information, visit cortado.ventures.

[1] Frictional loss leads to a decrease in the fluid’s pressure as it flows along the pipe. This decrease in pressure is essential to maintain a continuous and steady flow of the fluid.

[2] Long chains of hydrogens and carbons that are covalently bonded

[3] Rheological properties are the flow properties of materials that exhibit a combination of elastic, viscous and plastic behavior